General Model

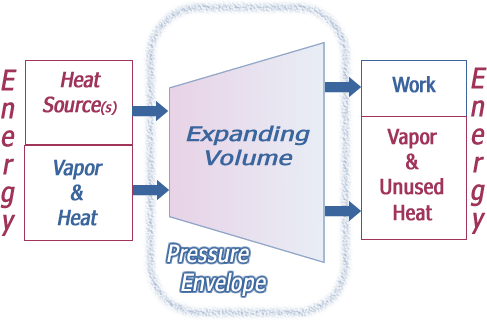

The general model of additive heat engine is that vapor is first placed in a constrained volume, then heated to create a pressure difference.

Technically, one could also create a pressure difference by subtracting heat, with a "cold" source. Also if there were vapor sources available at more or less than the pressure envelope. If such sources are ever developed, it is strait forward to create an engine from them.

The essential first step is creating a separate constrained volume(including being constrained by a turbine or propeller). Creating the pressure difference must come after constraining volume.

|

Heat recycling engine model

The heat recycling engine model requires multiple volumes "cooperating" to exchange heat and/or vapor.

In each step, volume containment comes first. Ideally, the containment comes from shutting a valve. The act of doing work by pushing against the vapor pressure to move it will in general defeat the purpose of heat recycling.

The intake must create containment before adding heat. All engines do that already. A heat recycling engine creates a separate containment before adding heat, so that heat can be added more than once before expansion.

An expansion will leave some unconverted heat in expanded vapor which is ready to be exhausted. That heat can be transferred to any cooler vapor, but only to the extent there is a temperature difference. If exhaust is initially at 220 C over ambient, but intake is heated 100 C over ambient before heat recovery, the intake can be raised to 220, and exhaust cooled to 100 C. 120 C is recoverable.

In general there are 3 cases. The intake is compressed on the insulated work curve, which heats the intake before heat recovery, the intake is compressed on an uninsulated curve, which requires less work but dissipates all the stored energy, and 3 the intake is not compressed. This would seem the ideal case, but it loses exportability of work. These 3 cases will be covered the next page in more detail.

In all cases, recycling means constraining the intake vapor, doing heat exchange, putting the partially heated air in the expansion chamber, adding fuel heat, expanding, exhausting to a third volume, which does heat exchange with an opposite intake, and finally exhausts vapor at approximately ambient.

The manner in which vapor is constrained and moved cannot create significant work, meaning at no time is the engine ever doing work to contain or move vapor that is proportional to its pressure. It isn't "pushed in" anywhere. So, simple concept, difficult solution, difficult implementation.

|