Steam Model

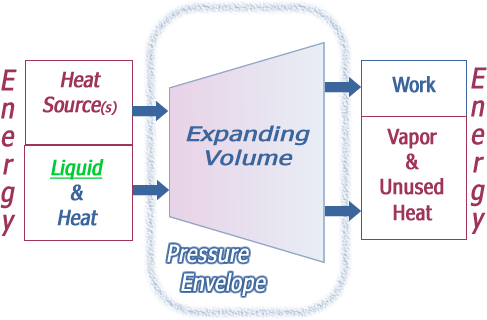

The general steam model is the same as the general model, except the starting point is a liquid.

|

Heat recycling steam engine model

The steam engine is typically used for electric generation. So often a very large device.

Also, there is no compression, and so none of the complications compression brings.

Recovering heat from steam for recycling is straightforward. However, by recovering all the heat, most importantly the heat of vaporization, a straightforward implementation ends up with steam. In turn, this means pushing steam into a boiler. This clearly takes as much work as the steam did on the way out of the boiler. So a successful recycling scheme must solve this problem.

Some portion of the work done is pushing the atmosphere out of the way. Another way to look at it is the atmosphere creates a back pressure on the turbine. This does not affect conversion, but does affect exportability of the work. In a straightforward system, a portion of the work done is lifting the atmosphere away from the turbines exhaust.

If the turbine operates at high pressure, 10 atmospheres and up, the portion lost because of exportability is approximately the ratio of the pressures, or 1/10 for a ten atmosphere device.

Most electric plants are between 35% and 60% efficient, depending on whether they are simple cycle or combined cycle. Neither comes close to what is achievable with recycling. In fact, a recycling plant should be both cheaper to manufacture and more fuel efficient.

|