|

|

Complete heat recycling yields a theoretical 100% conversion.

A serious look at heat recycling shows the "temperature ratio" limit does not exist for air (previous page disproves it for water/steam).

Below we show the apparently useless heat at the end of either type of compression cycle are equal to the amount of work to do the next cycle.

So if the mechanism instead of exhausting this heat, uses it to power a compression cycle, all heat is either used or recycled. The exportable work per cycle goes up by the amount of success achieved in recycling the compression heat.

Two "solvable" cases

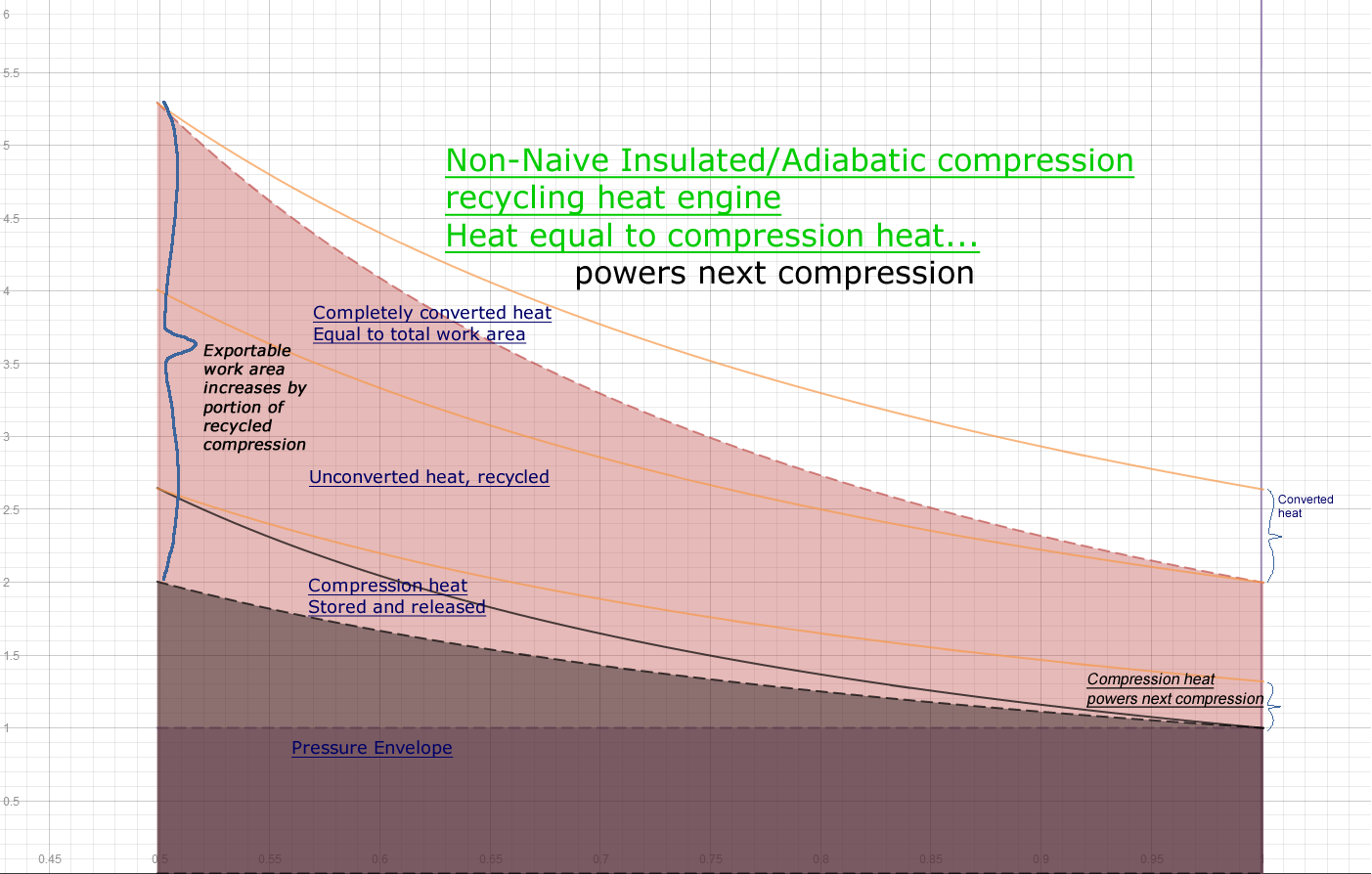

Case 1, insulated compression.

We note the unrecycled fuel heat, is exactly equal to the amount of energy needed to do the 2 to 1 compression.

So, instead of discarding it, it is also "recycled" to produce the compression needed for the next engine cycle.

This expands the area of exportable work, so brings the efficiency up.

An ideal mechanism discards no heat, so would create additional work by relieving the main engine cycle from doing the compression (a separate compression mechanism). The engine cycle shows the engine still contributing to compression, in the event recycling isn't 100% effective.

Is this possible with a real mechanism?

Yes, patent pending.

|

Graphs

|

|

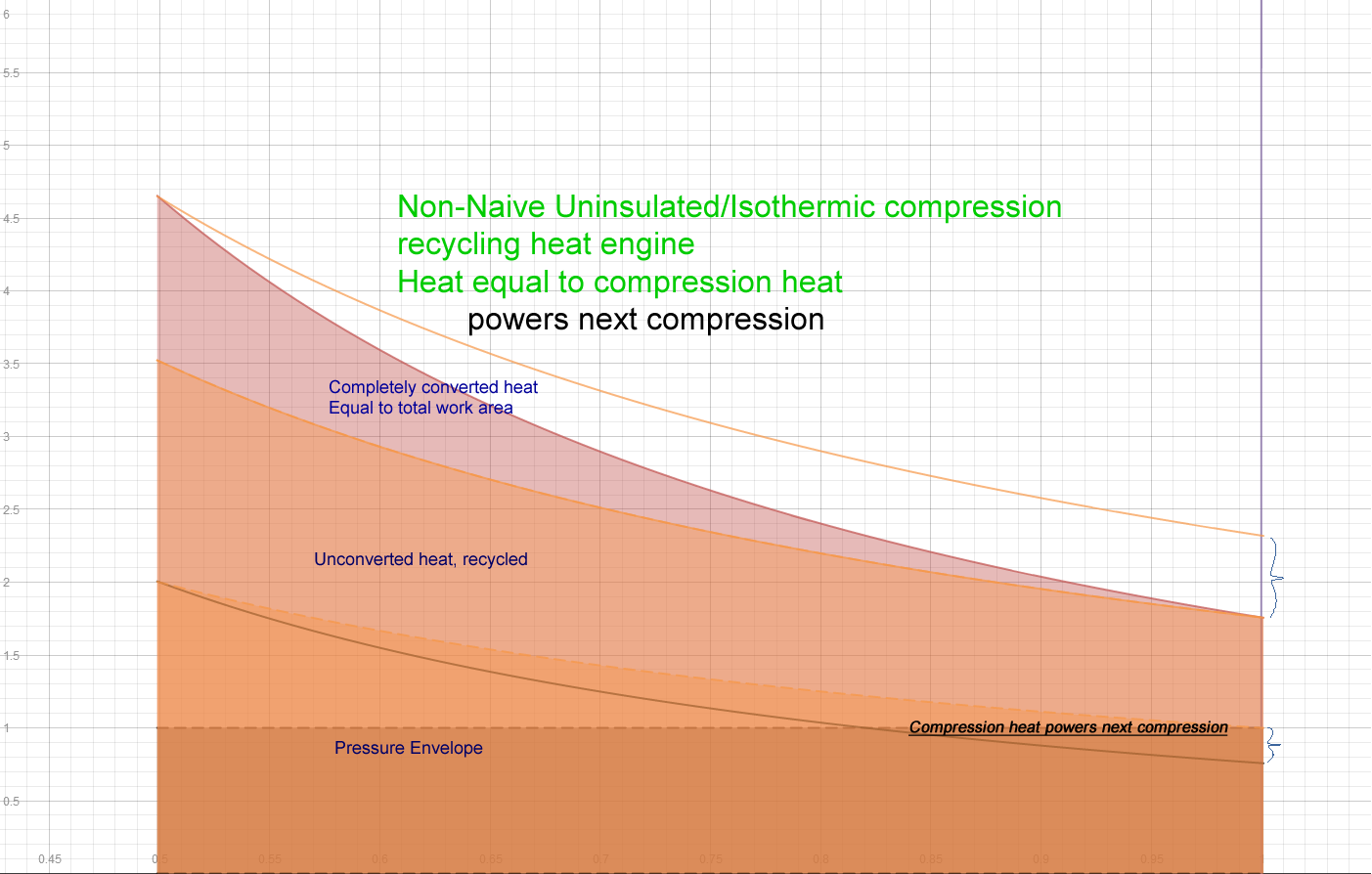

Case 2, uninsulated compression.

The unrecycled fuel heat, is again exactly equal to the amount of energy needed to do the 2 to 1 compression.

So, instead of discarding it, it is also "recycled" to produce the compression needed for the next engine cycle.

This also expands the area of exportable work, so brings the efficiency up.

A separate compression mechanism is still needed. The engine cycle shows shows the engine still contributing to compression, in the event recycling isn't 100% effective. The theoretical maximum is the same.

Is this possible with a real mechanism?

Yes, patent pending.

|

|

|

Case 3. Uncompressed cycle.

This case has both exportability issues as well as an apparent need to discard some heat.

The enclosable machine example solves this with iterative expansions, since the device still contains all the energy in a usable form. A practical device might for example do a single, partial return stroke. This would export part of the unexported work, most of it actually.

Its not clear how one could accomplish the trade off to recover the exhausted heat, as the temperatures have shifted down out of a useful range. At present, there is not a practical mechanism to bring this case to 100% efficiency. (Other than the iterative sequence of strokes and return strokes of diminishing length.) So not a theoretical limit, but a practical one.

|

|

|